It's finally happened !!!

- Thread starter Pantherman

- Start date

- Joined

- Sep 4, 2022

- Messages

- 1,514

Nice, just thinking about that today, not so much because of spill danger, just to control fumes... then while one hand holding part, use the other hand to open bottle.opening up this cement with one hand

blakeh1

Well-Known Member

- Joined

- Oct 26, 2011

- Messages

- 1,066

Oh no, sucks about the spill.

I think the worst modelling disaster I had was just finishing fully painting some figures, and before snapping some pics, deciding to dull coat them. Only instead of dull coat, I grabbed black spray paint and watched all my hard work get blacked out

I think the worst modelling disaster I had was just finishing fully painting some figures, and before snapping some pics, deciding to dull coat them. Only instead of dull coat, I grabbed black spray paint and watched all my hard work get blacked out

Last edited:

Littlemarten

Active Member

- Joined

- Dec 1, 2024

- Messages

- 180

Did you then proceed to ionize the local atmosphere?Oh no, sucks about the spill.

I think the worst modelling disaster I had was just finishing fully painting some figures, and before snapping some pics, deciding to dull coat them. Only instead of dull coat, I grabbed black spray paint and watched all my hard work get blacked out

One reason I no longer use rattle cans!

- Joined

- Mar 6, 2023

- Messages

- 2,133

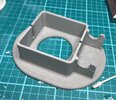

I printed out one of these for just that reason.Well after nearly 4 years of model building I have today knocked over the Tamiya extra thin, not just an old half full pot but a brand new pot bought yesterday......

Anyway it got me thinking if any of you have finally done something that you have seen or heard about that you thought you would never do ? Pantherman

Pantherman

Well-Known Member

- Joined

- Feb 10, 2022

- Messages

- 3,792

Got to get me one of them printers soon. PM

Littlemarten

Active Member

- Joined

- Dec 1, 2024

- Messages

- 180

That's how I started, but I was still knocking things over. Since starting with my current devices, I haven't knocked anything over.I'm cheap, I just use different sized aerosol caps.

Of course, now I've jinxed it.

Littlemarten

Active Member

- Joined

- Dec 1, 2024

- Messages

- 180

That stings. Do you "mark" the hole location with an awl or other pointed tool? That usually prevents the drill bit "walking."Teeny drill bit skates off part into finger tip.

Teeny blood sample anyone?

Very careful now, need those finger tips for guitar. Callus significantly limited the puncture!

- Joined

- Sep 4, 2022

- Messages

- 1,514

Oh yeah. Always.That stings. Do you "mark" the hole location with an awl or other pointed tool? That usually prevents the drill bit "walking."

I have a pointed scriber that works very well.

That time I must have pushed a little too hard, or gone off perpendicular, who knows.

And when its the end of a barrel, it doesn't have to skate very far!

Basically, off the rim.

Littlemarten

Active Member

- Joined

- Dec 1, 2024

- Messages

- 180

Whenever I have to drill something like that, or a small part, I clamp it in padded vice jaws. Most I'll lose is a drill bit, and maybe do some putty work on the part. Speaking of which, I'm about to drill out the gun barrels on the 1/32 Hasegawa P-40E. The OD is correct, but the ID is too large, and they are about 1/16 inch too long. That's going to be tedious. Then I'll sleeve the correct ID hypo tubing inside.Oh yeah. Always.

I have a pointed scriber that works very well.

That time I must have pushed a little too hard, or gone off perpendicular, who knows.

And when its the end of a barrel, it doesn't have to skate very far!

Basically, off the rim.

- Joined

- Sep 4, 2022

- Messages

- 1,514

Tried that, seems my hands work together to maximize precision...if one moves, the other compensates.padded vice jaws

Littlemarten

Active Member

- Joined

- Dec 1, 2024

- Messages

- 180

Except when it doesn't …Tried that, seems my hands work together to maximize precision...if one moves, the other compensates.

- Joined

- Sep 4, 2022

- Messages

- 1,514

I hear ya, not that far away for me... so trying to get in at least an hour of music a day, on one or other instrument, good for the noggin, good for coordination, flexibility and dexterity. And fun.At 74