Hagoth

Active Member

- Joined

- Mar 11, 2015

- Messages

- 493

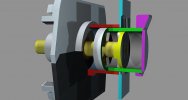

Introducing my current project. An upgraded S-foil positioning mechanism for my ancient 1:48 scale MPC X-Wing. As a kid I though it was pretty cool even though it is a bit wonky. Now that my engineering side has focused on it there are all kinds of issues. The wings rock independent of the body. They do not open in a synchronized manner and can move independent of each other. You can see through the model side to side and the back and front of the wing box are open. Also, through no fault of the design, the wings are sagging.

I have set out to create a mechanism that fixes all those problems. Here are the results so far.

http://hagoth.wix.com/the-brass-ball#!pm-1a/cjex

While this current project (named PM-1A) is designed for the 1:48 scale MPC X-wing the concept can be adapted to 1:35 scale and 1:24 scale very easily. It can also be easily motorized in any of the scales.

I'm interested in feedback on the concept so far for any scale but especially from those that have the old MPC model (built or not) as this mechanism will likely end up as an upgrade kit for it soon.

I have set out to create a mechanism that fixes all those problems. Here are the results so far.

http://hagoth.wix.com/the-brass-ball#!pm-1a/cjex

While this current project (named PM-1A) is designed for the 1:48 scale MPC X-wing the concept can be adapted to 1:35 scale and 1:24 scale very easily. It can also be easily motorized in any of the scales.

I'm interested in feedback on the concept so far for any scale but especially from those that have the old MPC model (built or not) as this mechanism will likely end up as an upgrade kit for it soon.