Space Robots from Outer Space

- Thread starter Fungi

- Start date

- Joined

- Sep 4, 2022

- Messages

- 1,454

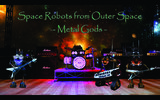

Nice! I guess we'll have to update that terrible old musician's joke: "How to tell if the stage is level?"completed the basic drum setup

... check which side drool(lubricant) is coming out of the drummer's mouth(service port)!

Littlemarten

Active Member

- Joined

- Dec 1, 2024

- Messages

- 163

Just incredible!

- Joined

- Sep 4, 2022

- Messages

- 1,454

Nice! Meteor shower nice touch!video

Littlemarten

Active Member

- Joined

- Dec 1, 2024

- Messages

- 163

You continue to amaze—and I absolutely love the cat!

- Joined

- Sep 4, 2022

- Messages

- 1,454

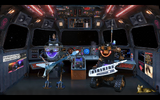

Hahaha, ship navigation and controls, a digital soundboard... could it be anything other?!space ship interior

Littlemarten

Active Member

- Joined

- Dec 1, 2024

- Messages

- 163

Faaarrrr freakin' out!

trekriffic

Well-Known Member

- Joined

- Jan 6, 2012

- Messages

- 1,019

So cool to see this real metal band performing. You really have hit this into orbit!

Similar threads

- Replies

- 8

- Views

- 824

Latest posts

-

-

-

Boatmans 1/32 scale super tomcat with lights an opening engine hatches

- Latest: Littlemarten

-

-

-

-

-