1/144 german destroyer class 119 revell

- Thread starter domer94

- Start date

i was impressed with the kit quality. so much so , i think it would turn out really nice right out of the box as well and i dont say that about many. i believe this is the same hull as their 1/144 fletcher , which i have in the stash as well someplace.@domer94 How are you liking the kit over all at this point? Is the fit good? I'm very interested in giving a kit this size a try. Your build is looking amazing and the attention to detail is outstanding.

Calico Jack

Well-Known Member

- Joined

- Jan 8, 2025

- Messages

- 174

That's great to hear. I've been looking for the Fletcher for a long time, but no one has it and it's discontinued.i was impressed with the kit quality. so much so , i think it would turn out really nice right out of the box as well and i dont say that about many. i believe this is the same hull as their 1/144 fletcher , which i have in the stash as well someplace.

there one on ebay , but its in italy and priced ridiculously...That's great to hear. I've been looking for the Fletcher for a long time, but no one has it and it's discontinued.

Edbert

Well-Known Member

- Joined

- May 16, 2024

- Messages

- 1,062

It should be the same, these were Germany's early DDs after WWII (1950s) and the US leased six Fletcher-class ships to them as a base to build on.i believe this is the same hull as their 1/144 fletcher , which i have in the stash as well someplace.

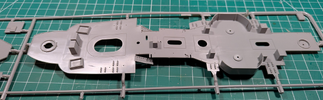

Seeing your build caused me to pull the trigger and get this off my wish list. Then I saw the shot with all the clamps and wanted to see what shape mine was in.

First thought upon opening the box is oh damn what did I bite off here, almost 1,800 parts. The instructions were pretty modest, then I found the many pages of color instructions just for the PE! I think this one will take many months to complete.

So I dug in to find the largish part of the (sorry, do not know the right terms) upper-deck, and my heart sank.

A bit hard to see in that shot, but there's a few compound curves, simply warped into a mess.

This shows it a bit better. Think I have only two options; contact the manufacturer and show them this asking for a new part, or get the heat gun and hand-weights out. Those ladders will be an issue for option #2.

The box is quite large, but about 0.25 inch too narrow, two of the sprues had to bend to fit inside of it. That was NOT the cause of the warpage illustrated above, the sprues that did not lie flat inside the cardboard had smaller parts that seem to be okay.

Last edited:

thats a bummer... the ladders will come off anyhow for PE, plus you will have to remove all the molded deck boxes so you will be left with a mostly flat piece. i would try to get a new one , but in the meantime see if you can heat / flatten after all the removals. good luck. another note , there are spare sprues... they allow for another 5" gun , and another AA assemblyIt should be the same, these were Germany's early DDs after WWII (1950s) and the US leased six Fletcher-class ships to them as a base to build on.

Seeing your build caused me to pull the trigger and get this off my wish list. Then I saw the shot with all the clamps and wanted to see what shape mine was in.

First thought upon opening the box is oh damn what did I bite off here, almost 1,200 parts. The instructions were pretty modest, then I found the many pages of color instructions just for the PE! I think this one will take many months to complete.

So I dug in to find the largish part of the (sorry, do not know the right terms) upper-deck, and my heart sank.

View attachment 140682

A bit hard to see in that shot, but there's a few compound curves, simply warped into a mess.

View attachment 140683

This shows it a bit better. Think I have only two options; contact the manufacturer and show them this asking for a new part, or get the heat gun and hand-weights out. Those ladders will be an issue for option #2.

The box is quite large, but about 0.25 inch too narrow, two of the sprues had to bend to fit inside of it. That was NOT the cause of the warpage illustrated above, the sprues that did not lie flat inside the cardboard had smaller parts that seem to be okay.

thats a bummer... the ladders will come off anyhow for PE, plus you will have to remove all the molded deck boxes so you will be left with a mostly flat piece. i would try to get a new one , but in the meantime see if you can heat / flatten after all the removals. good luck. another note , there are spare sprues... they allow for another 5" gun , and another AA assembly. they also call for removing the life raft racks for PE , i opted to keep the kit moldings

pretty much finished with the main mast... this was a multi day build on its own. level upon level. i think its at the stage to paint today though. so whats worse than building one PE raday array? ... building two ! i only entered the world of PE a couple of years back.. as much as my work has much to be desired, i feel i learn something every time. that being said , my feeling about PE is love hate. i watch vids about PE work and see people just touching the bottom of a piece in a puddle of glue , then simply attaching and letting go with the piece staying perfectly in place. thats happened about 1 in 10 times for me and ive tried every PE glue. i can t work off a "puddle" since it wastes a large amount of adhesive. i found this stuff , which is similar to gators grip... again , putting a puddle and working off that leads to it setting up and being useless after 10 minutes. so ive used this with some fine applicators found in bulk. the tips fit perfect. but still... it doesnt happen like the videos! i guess my view on PE is its all relative... putting in gussets onto a small platform that are the size of a pinhead doesnt make sense to me. if i was working in 1:96 or larger , it would make more sense. and certain assemblies that have 10 parts for one handwheel... i dont know. guess i dont have the skill for that yet

- Joined

- Sep 4, 2022

- Messages

- 1,535

Dunno, looks like you have plenty to me!skill

With vehicles, PE can and does get pretty small, but there isn't an overwhelming amount to deal with as with ships...

I've tried the accelerator route, but often I just don't have enough hands! And I find that it is just as likely to 'freeze' CA in an ugly crystal blob that needs filing or sanding afterwards.

In other threads, folks have suggested just breathing on it before letting go... that seems to work, and doesn't require an extra hand!

I have tried many glues as well (gonna see if yours is available here)... lately, in some circumstances, a gel CA applied to the target, then putting the part into it, has also worked. With a gel, the CA doesn't tend to run away and for teeny parts, the gel holds it in place for those critical microseconds as the CA sets...

I may have mentioned it elsewhere, but while testing materials for a ragtop, I discovered that Ziploc Freezer Bags peel away from CA... so I'm less concerned about gluing parts to the bench especially when using an extra thin CA, if the parts are resting on the bag.

Anyhow, looking great, keep with it!

just fyi , i found that particular glue on ebay. i found that letting it sit for a couple of minutes on the surface of application , gives better success of holding in place when the piece is put on. the nozzle it comes with is useless. with the plastic detail applicator tips , you can use the "tool" it comes with , or a pin to put inside the applicator to make it work for several days of use. i plug it after every application.Dunno, looks like you have plenty to me!

With vehicles, PE can and does get pretty small, but there isn't an overwhelming amount to deal with as with ships...

I've tried the accelerator route, but often I just don't have enough hands! And I find that it is just as likely to 'freeze' CA in an ugly crystal blob that needs filing or sanding afterwards.

In other threads, folks have suggested just breathing on it before letting go... that seems to work, and doesn't require an extra hand!

I have tried many glues as well (gonna see if yours is available here)... lately, in some circumstances, a gel CA applied to the target, then putting the part into it, has also worked. With a gel, the CA doesn't tend to run away and for teeny parts, the gel holds it in place for those critical microseconds as the CA sets...

I may have mentioned it elsewhere, but while testing materials for a ragtop, I discovered that Ziploc Freezer Bags peel away from CA... so I'm less concerned about gluing parts to the bench especially when using an extra thin CA, if the parts are resting on the bag.

Anyhow, looking great, keep with it!

- Joined

- Sep 4, 2022

- Messages

- 1,535

Ha! I have the same tips, bulk buy... and I trim them about half length and half of the base for a snug fit on CA bottles, and just sit the cap on them... they rarely clog, and when they do, 1/8 " snip usually does the trick. I don't know if being technically 'open' means there is some essential ingredient evaporating away, but I've left them like that for months! It works with thin and medium CA, as well as the 'de-glue' stuff.i plug it

kevin

Well-Known Member

- Joined

- Mar 21, 2024

- Messages

- 343

I'm just now getting into the PE from the Pontos kit for my USS IOWA. Six pieces for a capstan about the size of a grain of rice! This is a Bofors gun tub with 11 PE parts for the ammo racks, my second one out of 19 to do. The first one was an abortion, and will not be photographed . I'm using this glue with a sharpened tooth pick as an applicator. I apply the glue directly to the end of the toothpick.

Your main mast is looking good.

Your main mast is looking good.

Last edited:

Edbert

Well-Known Member

- Joined

- May 16, 2024

- Messages

- 1,062

I am no authority, but I think Micro Mark is relabeling BSI, Bob Smith Industries product. I've had good luck with their "Maxi-Cure Extra Thick", although it dries too fast for the puddle technique IMO. I also use BSI flexible CA, do not know why but it is black not clear. It does flex a little, but only compared the hard stuff, it is not silicone or anything like that.

Regarding the use of accelerators, I have had some luck with an aerosol can of it. However, you must be sure there's not tiny bits all over the bench or they'll be blown into oblivion with a velocity like few tweezers can accomplish.

Good tip on the ziplocks, I've been using a flat piece of steel that I need to clean off with acetone from time to time.

Regarding the use of accelerators, I have had some luck with an aerosol can of it. However, you must be sure there's not tiny bits all over the bench or they'll be blown into oblivion with a velocity like few tweezers can accomplish.

Good tip on the ziplocks, I've been using a flat piece of steel that I need to clean off with acetone from time to time.

- Joined

- Sep 4, 2022

- Messages

- 1,535

still pluggin on the "this and that" final details. looking at the ship i think something was missing.. ive never seen a vessel with no deck fire stations. i found some USN 1/144 details on ebay and started installing tonight. i like the look. comes with the fire main connection pipe and the hose rack. also added couple more decals , some boat davit details.. i added gripes / straps made out of spare brass. also ran a sea painter from the boat bow to the chock forward and onto the bitts. have to find some fire axes now

Last edited:

- Joined

- Sep 4, 2022

- Messages

- 1,535

... oh, the little details! I've not served on a ship, but every time I'm on a ferry or large boat, my camera is drawn to the ubiquitous painted accessories, and how they make the space more official and functional feeling. 'Shippy' things you're not going to see anywhere else!

Good on you to find and make these great additions.

Good on you to find and make these great additions.

Edbert

Well-Known Member

- Joined

- May 16, 2024

- Messages

- 1,062

WAIT!still pluggin on the "this and that" final details. looking at the ship i think something was missing.. ive never seen a vessel with no deck fire stations. i found some USN 1/144 details on ebay and started installing tonight. i like the look. comes with the fire main connection pipe and the hose rack. also added couple more decals , some boat davit details.. i added gripes / straps made out of spare brass. also ran a sea painter from the boat bow to the chock forward and onto the bitts. have to find some fire axes now

A kit ships with ~1,800 parts and your brain says "I need aftermarket"?