1/48 Hobbygawa Fw293A-2 / U1

- Thread starter urumomo

- Start date

Davey

New Member

- Joined

- Oct 9, 2022

- Messages

- 16

Can't wait to see how this turns out.

urumomo

Well-Known Member

- Joined

- Mar 18, 2013

- Messages

- 7,754

Placing the cockpit farther aft allows for , conservatively , a 125 gallon / 473 L fuel tank

According to this --> https://www.deutsches-museum.de/en/flugwerft-schleissheim/ausstellung/flugantriebe-und-raketen/jumo-004#:~:text=Fuel consumption: 1273 kg/h

that JUMO 004 burns 1273 Kg/hr

Using 830 grams/ L for the fuel mass gives 378.4 Kg of fuel

( fuel density range is 815 to 845 g/L , from --> https://ww2-history.fandom.com/wiki/Junkers_Jumo_004_Engine )

About 19 minutes of the engine doing engine stuff .

So a generous compliment of JATO bottles on takeoff it is then ..

According to this --> https://www.deutsches-museum.de/en/flugwerft-schleissheim/ausstellung/flugantriebe-und-raketen/jumo-004#:~:text=Fuel consumption: 1273 kg/h

that JUMO 004 burns 1273 Kg/hr

Using 830 grams/ L for the fuel mass gives 378.4 Kg of fuel

( fuel density range is 815 to 845 g/L , from --> https://ww2-history.fandom.com/wiki/Junkers_Jumo_004_Engine )

About 19 minutes of the engine doing engine stuff .

So a generous compliment of JATO bottles on takeoff it is then ..

urumomo

Well-Known Member

- Joined

- Mar 18, 2013

- Messages

- 7,754

scalebuilderchad

Active Member

- Joined

- Aug 31, 2023

- Messages

- 191

This is so cool!!!

urumomo

Well-Known Member

- Joined

- Mar 18, 2013

- Messages

- 7,754

Haha , hopefully .

I had the air intake portion just about done , what can be done prior to installing the cowling , but I kept accidently sanding a radius into the vertical nose ,

so I embedded a 1.15 mm SS rod there . -- makes it 55 mm thick @ 1:1

Should have that primed and top coated with airframe aluminum tomorrow .

Then finish it off thru that 16 mm opening .

Should be interesting .

I hot glued bits of sanding sponge to sticks to smooth out the transition into the pipe ,

I had the air intake portion just about done , what can be done prior to installing the cowling , but I kept accidently sanding a radius into the vertical nose ,

so I embedded a 1.15 mm SS rod there . -- makes it 55 mm thick @ 1:1

Should have that primed and top coated with airframe aluminum tomorrow .

Then finish it off thru that 16 mm opening .

Should be interesting .

I hot glued bits of sanding sponge to sticks to smooth out the transition into the pipe ,

scalebuilderchad

Active Member

- Joined

- Aug 31, 2023

- Messages

- 191

I just started doing something like this recently. I was having trouble sanding in tight spaces so I started gluing sandpaper to the end of plastic sprues.Haha , hopefully .

I had the air intake portion just about done , what can be done prior to installing the cowling , but I kept accidently sanding a radius into the vertical nose ,

so I embedded a 1.15 mm SS rod there . -- makes it 55 mm thick @ 1:1

Should have that primed and top coated with airframe aluminum tomorrow .

Then finish it off thru that 16 mm opening .

Should be interesting .

I hot glued bits of sanding sponge to sticks to smooth out the transition into the pipe ,

View attachment 132283

urumomo

Well-Known Member

- Joined

- Mar 18, 2013

- Messages

- 7,754

I'll probably need to make something up for working the inside thru that tiny opening .

If Santa would return my calls , you'd have an ultrasonic knife in his sleigh

but

alas , you will need to buy it your own self .

Get one before they stop making them , at least .

If Santa would return my calls , you'd have an ultrasonic knife in his sleigh

but

alas , you will need to buy it your own self .

Get one before they stop making them , at least .

urumomo

Well-Known Member

- Joined

- Mar 18, 2013

- Messages

- 7,754

Haven't felt like editing and uploading pix for whatever reason .

I started into this thing months ago but realized I needed to finish out the cockpit before I could start playing with components ,

so , it stalled out since I wasn't in the mood for the micro-work .

Same reason that BV 155 isn't complete -- never been in the mood to fabricate the antenna wire with the tiny spring and attachment hardware , plus the tail and fuselage anchor points .

That one is 1/72 , too . , so even more fun .

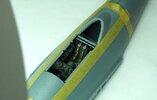

That Hobby Beast 262 kit has all kinds of internal details that you would never see when it's all together .

They put a lot of effort into that thing .

BTW ,

MERRY CHRISTMAS !!!

The cowling is ready to be permanently installed and then the remainder of the intake finished out .

It really needs some panel lines in there but I don't think I'm going that far with it .

I might still do it .

maybe .

possibly ?

Stynylrez primer and Alclad airframe aluminum ( it will get dulled down in the end ,

Similar threads

- Replies

- 1

- Views

- 305