- Joined

- Jan 27, 2011

- Messages

- 205

Keeps getting better .

So cool

Thank you.

.............................................

Back into it after a brief distraction of real world studio recording adventures with my fellow band mates.

My original plan was to leave some of the back area of the pod bare to house my battery clip but that all change as I redid my wiring for the pod lighting because the normal gauge wire was just too bulky and was a pain to try and route due to it's springing nature that made it awkward to tuck out of the way.

I rewired a set of fairy lights that come with some 28 AWG magnetic copper wire which is perfect for bending and holding it's shape, I may go back and rewire the main cockpit fuselage with this wire as I think it's way easier to work with and besides, since I'm running my LED's from a DC source there's really no need for thick wire since we're only talking milliamps and not high powered mega watts of current.

Also decided that three LED's were plenty to light the pod interior rather than six (two rows of three), I wired three SMD's for the fiber optic filament as I didn't want all the strands (ten in total) to be dependant on just one source as each bunch which consisted of 4x 4x 2x strands were targeted for a specific area.

Dry fitted the new lighting which is way more tidier than the recent rats nest.

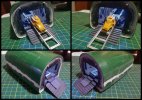

As you can see I made a few adjustments to the pod by adding some structural beams as these would also act as support for my lighting, they presented a bit of a challenge to curve to the shape and correct size of the pod interior, they aren't perfect but they serve their purpose, I also drilled random holes in them just for added detail.

For the battery clip, I used the space under the floor for the compartment but then realising in doing that, the whole rear bulkhead had to be removable if I wanted to access the clip to change batteries or even turn the lights on and off. I applied the neodymium magnets trick for the rear bulkhead and the rear doors outer plate.

I'm at the moment trying to source some thin rubber seal to light block around the edge of the bulkhead, I was thinking of using some of the softer foam kind that conforms easily.

Another light test as I've been doing a bunch of them after every step just to make sure everything still works, all seems well.

Now that the bulk of the work is done on the pod I'm left with adding some greeblie detailing here and there to fill space, one final lighting test and finally paint the interior then seal the top and lower sections together.

Thanks for looking.

Cheers