Thereal9thdoctor

Well-Known Member

- Joined

- Jun 27, 2021

- Messages

- 571

Thanks! Turned out better than I expected.

Heh. He is a peepiing Vulcan.Who's the creeper in the window?

Thanks. Learning alot from this build.Looks like the work you're putting in is paying off

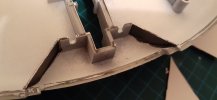

The post on the fan that fits onto the motor should be straight; it leans to one side, which means its not gonna spin right and could possibly break while running besides looking stupid since one dome would be normal and this one would not sit level in the engine.Since I'm just along for the ride -

what is the issue ? the post at the center of the Bussard shouldn't be there ?

what is " PL " ?

Can't you get a receipt for the Enterprise kit from where you purchased it ? -- With it you can get free parts ? replacement parts ? or ? ,, very confused .

A different fan kit will fit the Bussard you have or you get a 3D-print Bussard that will work with the PE fan you have ?

I will try one of those ideas. Thanks.i remember this issue with the bussards from when I got my kit eight years ago. As I recall some modellers said they were able to heat the bussard dome using a hair dryer getting it hot enough to soften the plastic and straighten the shaft. Another option would have been to carefully drill several small holes close together around the perimeter of the shaft, drilling from the front of the bussard spinner dome. before using a sharp exacto knife to slice thru the remaining plastic between the holes. Once the shaft was free you could glue it back in after repositioning it. The photoetch includes a round brass piece to fit the recess in the center of the hub on the front of the spinner which would effectively cover up the repair work.

You could try either one of these fixes and if it didn't work you're not out anything but your time and effort since you coild still purchase a replacement spinner dome from PL.

One thing about using the heat method is you need to be careful and not get the part so hot it warps the circumference of the spinner. I could see someone heating it then holding the part too tightly in their fingers as they straightened the shaft only to end up with an oval dome. I myself have a heat gun but I think that would probably get the part too hot, a hairdryer might work bette. Heat it up and move the shaft a little bit, apply more heat then move it a little more. Don't try to do it all at once and maybe turn the spinner in your hand a tad each time.I will try one of those ideas. Thanks.

I plan on the second method. No heatgun or hairdryer, and my GF would F.L.I.P. if I used hers.One thing about using the heat method is you need to be careful and not get the part so hot it warps the circumference of the spinner. I could see someone heating it then holding the part too tightly in their fingers as they straightened the shaft only to end up with an oval dome. I myself have a heat gun but I think that would probably get the part too hot, a hairdryer might work bette. Heat it up and move the shaft a little bit, apply more heat then move it a little more. Don't try to do it all at once and maybe turn the spinner in your hand a tad each time.