I forgot how time consuming all this figure clean-up is

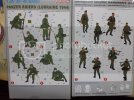

All of these guys in this round are from Dragon - a lotta half-heads :

I'm not opposed to using the half-heads if they look good and have the appropriate expression , but so far it's been a steady Hornet Head swap ..

.. this face isn't bad but the expression is wrong .

He looks like he's waiting for you to decide on your ice cream order -

- not breathing Jagd fumes :

The tools used for figure clean-up :

... that little 1 mm flat file from Wave and the .25 mm needle file from Mineshima are indispensable

. .. . more Stick-In-Boot ,, gonna keep some of them ( I guess . For now )

The detail overall is pretty good -

The torso at left is untouched and the one at right has been hollowed out for the Hornet Head install and the collars cut loose , and ( hard to tell here ) the strap has been defined further .

The torso at left will get the same treatment for the collars etc . - although that one barely needs it 8)

Now --- the madness that is the

Panther K Quad Eight

I added the additional magnets including another in the front of the turret to counter the " step-motor " characteristic of the setup -

It would be much simpler if there was steel on one side and a couple of magnets on the other - - - but I searched the parts bins when I began all this and couldn't find a suitable washer-esque component to bond to the hull roof ... and I wasn't going to fabricate one ( though I probably should have

)

---- I welded those two pieces of 2 mm styrene scrap to the roof to stiffen it .

The magnets were bowing the roof up while trying to get to the turret , heh heh

How far she swings until she gets to the engine hatch :

PLENTY

Hhmmmm - you can see an anomaly there inside the hull ;D

I had to cut the very last swing-arm free and make it poseable -

Since it was welded in there ,

I had to cut it out and in the process remove the upper portion of the socket .

I just used Aves Epoxy Sculpt to construct a new socket ---- and a wood screw through a pilot hole is a done-deal .

The little piece of styrene tube stock is there to provide additional anchorage for the Aves ( has anchor holes drilled into it and its welded to the hull floor )

I always prefer mechanical bonds / interlocks with epoxy . They all have iffy adhesion with plastics -- that

Locktite clear , 5 min epoxy was pulling away at that end . Not a surprise . I had to add to the first epoxy pour last week since 3 of the nuts were promptly jacked right out by the screw ;D -- again , not surprised .

Going the Aves /wood-screw route may be arguably the better method ....

I'm working on a little prototype for a torsion spring suspension unit for this - or other torsion bar suspension tanks .

It installs and works pretty much like the 1:1 version , and is adjustable .